Our HydroPro™ Hydronic Control Panels provide contractors a custom fully engineered solution designed and manufactured specifically to their application needs and include the finest quality components. These panels are designed to reduce on-site time, increase quality, and reduce space compared to site-built systems. Eagle Mountain has revolutionized hydronic panel building methods that provide the highest-level quality with short lead times, and our systems are pressure tested to 60 psi and all electrical operations are tested.

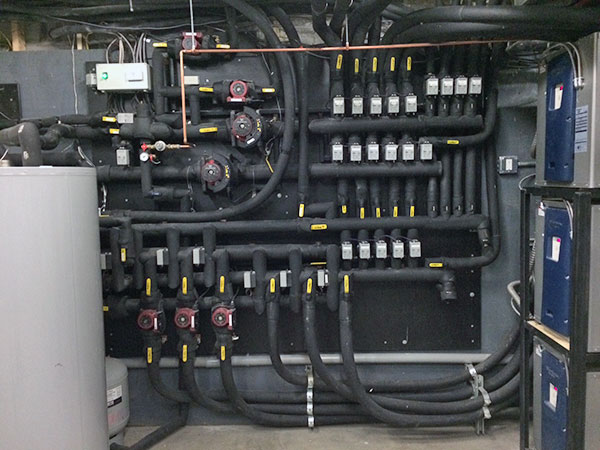

Our wall-mount panels are mounted on indestructible HDPE back panels with an integrated wall mounting system. All of the equipment is designed to be accessible for servicing and insulating.

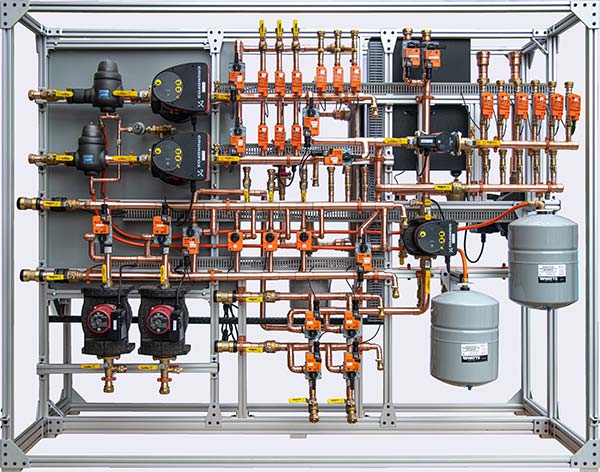

Eagle Mountains unique frameset systems are built into a free-standing aluminum frame that allows the system to be located centrally in the mechanical room, with access on both sides. We often include multiple devices such as the hydronic panel and the geothermal flow center both mounted on the same frameset on opposing sides

Standard features such as air removal, feed water control, expansion tanks, variable speed pumps, flushing and filling ports, combine to make our panel systems an excellent choice for the quality conscious contractor. Options are extensive and include features such as stainless or titanium heat exchangers, auto glycol fill systems, integrated boilers, and aluminum frame systems, make for complete adaptability to any type of application.

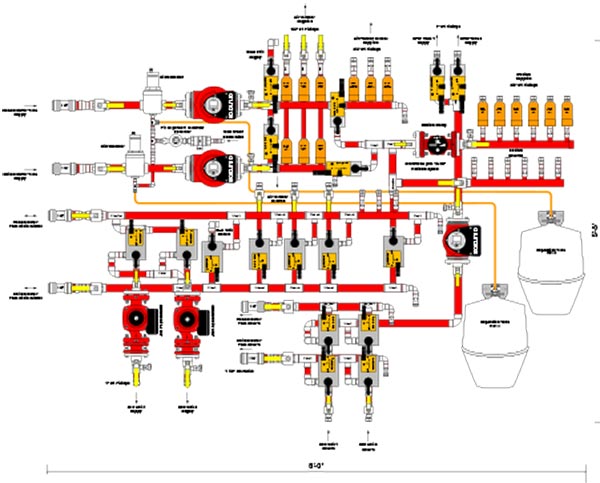

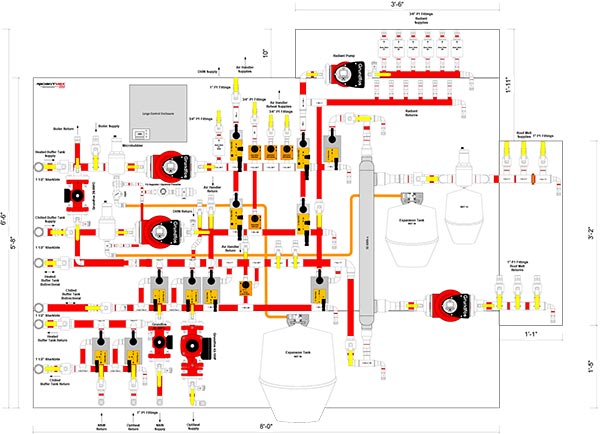

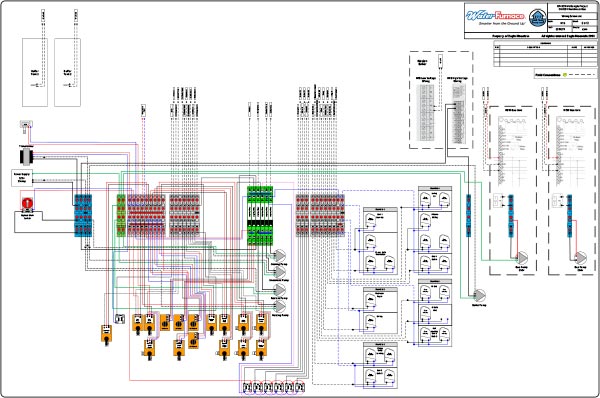

Every panel is custom designed by our engineering team. We produce the drawings necessary for production and then send them to the customer for approval. Eagle Mountain also provides the electrical schematic that will include all of the components that are controlled by our system.